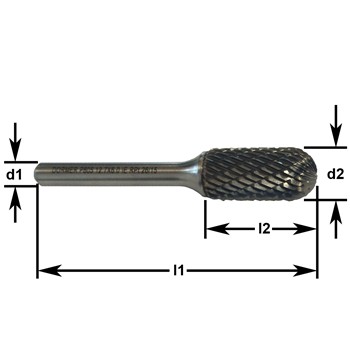

Fraise lime rotative en carbure sphérique ref. p805

*Excellent pour:

-1.1 Acier doux | Resist. traction: <400 N/mm² | Dureté: <120 HB (ISO: P1).

-1.2 Acier de construction/cementacion | Resist. traction: <700 N/mm² | Dureté: <200 HB (ISO: P1).

-1.3 Acier au carbone ordinaire | Resist. traction: <850 N/mm² | Dureté: <250 HB (ISO: P2).

-1.4 Acier allié | Resist. traction: <850 N/mm² | Dureté: <250 HB (ISO: P3).

-1.5 Acier allié/trempé et revenu | Resist. traction: >850<1200 N/mm² | Dureté: >250<350 HB (ISO: P4).

-1.6 Acier allié/trempé et revenu | Resist. traction: >1200<1620 N/mm² | Dureté: >350 HB (ISO: H1).

-1.7 Acier allié trempé | Resist. traction: >1620 N/mm² | Dureté: 49-55 HRC (ISO: H3).

-1.8 Acier allié trempé | Resist. traction: >1980 N/mm² | Dureté: 55-63 HRC (ISO: H4).

-2.1 Acier inoxydable de décolletage| Resist. traction: <850 N/mm² | Dureté: <250 HB (ISO: M1).

-2.2 Acier inoxydable Austénitique | Resist. traction: <1100 N/mm² | Dureté: <320 HB (ISO: M3).

-2.3 Acier inoxydable Ferritique + Austénitique, Martensitique | Resist. traction: <1000 N/mm² | Dureté: <300 HB (ISO: M2).

-2.4 Acier inoxydable Trempé| Resist. traction: >320<410 N/mm² | Dureté: >1100<1400 HB (ISO: S2).

-3.1 Fonte graphite lamellaire | Resist. traction: >500 N/mm² | Dureté: <150 HB (ISO: K1).

-3.2 Fonte graphite lamellaire | Resist. traction: >500<1000 N/mm² | Duretéa: >150<300 HB (ISO: K2).

-3.3 Fonte graphite nodulaire/ Fonte malléable | Resist. traction: <700 N/mm² | Dureté: <200 HB (ISO: K3).

-3.4 Fonte graphite nodulaire/ Fonte malléable | Resist. traction: >700<1000 N/mm² | Dureté: >200<300 HB (ISO: K4).

-4.1 Titane non allié | Resist. traction: <700 N/mm² | Dureté: <200 HB (ISO: S1).

-4.2 Titane allié | Resist. traction: <900 N/mm² | Dureté: <270 HB (ISO: S2).

-4.3 Titane allié | Resist. traction: >900<1250 N/mm² | Dureté: >270<350 HB (ISO: S3).

-5.1 Nickel non allié | Resist. traction: <500 N/mm² | Dureté: <150 HB (ISO: S1).

-5.2 Nickel allié | Resist. traction: >900 N/mm² | Dureté: <270 HB (ISO: S2).

-5.3 Nickel allié | Resist. traction: >900<1200 N/mm² | Dureté: >270<350 HB (ISO: S3).

-6.2 ß-Laiton, bronze | Resist. traction: <700 N/mm² | Dureté: <200 HB (ISO: N4).

-6.3 a-Laiton | Resist. traction: <700 N/mm² | Dureté: <200 HB (ISO: N3).

-6.4 Metal AMPCO | Resist. traction: <1500 N/mm² | Dureté: <470 HB (ISO: N4).

-9.1 Matières dures cermets (céramiques métalliques) | Resist. traction: <1700 N/mm² | Dureté: <550 HB (ISO: H).

*Bon pour:

-6.1 Cuivre | Resist. traction: <350 N/mm² | Dureté: <100 HB (ISO: N3).

- Matériel : Carbure

- Revêtement: Brillant

- Type: double coupure pour utilisation générale

|

Fraise lime rotative en carbure sphérique ref. p805

*Excellent pour:

-1.1 Acier doux | Resist. traction: <400 N/mm² | Dureté: <120 HB (ISO: P1).

-1.2 Acier de construction/cementacion | Resist. traction: <700 N/mm² | Dureté: <200 HB (ISO: P1).

-1.3 Acier au carbone ordinaire | Resist. traction: <850 N/mm² | Dureté: <250 HB (ISO: P2).

-1.4 Acier allié | Resist. traction: <850 N/mm² | Dureté: <250 HB (ISO: P3).

-1.5 Acier allié/trempé et revenu | Resist. traction: >850<1200 N/mm² | Dureté: >250<350 HB (ISO: P4).

-1.6 Acier allié/trempé et revenu | Resist. traction: >1200<1620 N/mm² | Dureté: >350 HB (ISO: H1).

-1.7 Acier allié trempé | Resist. traction: >1620 N/mm² | Dureté: 49-55 HRC (ISO: H3).

-1.8 Acier allié trempé | Resist. traction: >1980 N/mm² | Dureté: 55-63 HRC (ISO: H4).

-2.1 Acier inoxydable de décolletage| Resist. traction: <850 N/mm² | Dureté: <250 HB (ISO: M1).

-2.2 Acier inoxydable Austénitique | Resist. traction: <1100 N/mm² | Dureté: <320 HB (ISO: M3).

-2.3 Acier inoxydable Ferritique + Austénitique, Martensitique | Resist. traction: <1000 N/mm² | Dureté: <300 HB (ISO: M2).

-2.4 Acier inoxydable Trempé| Resist. traction: >320<410 N/mm² | Dureté: >1100<1400 HB (ISO: S2).

-3.1 Fonte graphite lamellaire | Resist. traction: >500 N/mm² | Dureté: <150 HB (ISO: K1).

-3.2 Fonte graphite lamellaire | Resist. traction: >500<1000 N/mm² | Duretéa: >150<300 HB (ISO: K2).

-3.3 Fonte graphite nodulaire/ Fonte malléable | Resist. traction: <700 N/mm² | Dureté: <200 HB (ISO: K3).

-3.4 Fonte graphite nodulaire/ Fonte malléable | Resist. traction: >700<1000 N/mm² | Dureté: >200<300 HB (ISO: K4).

-4.1 Titane non allié | Resist. traction: <700 N/mm² | Dureté: <200 HB (ISO: S1).

-4.2 Titane allié | Resist. traction: <900 N/mm² | Dureté: <270 HB (ISO: S2).

-4.3 Titane allié | Resist. traction: >900<1250 N/mm² | Dureté: >270<350 HB (ISO: S3).

-5.1 Nickel non allié | Resist. traction: <500 N/mm² | Dureté: <150 HB (ISO: S1).

-5.2 Nickel allié | Resist. traction: >900 N/mm² | Dureté: <270 HB (ISO: S2).

-5.3 Nickel allié | Resist. traction: >900<1200 N/mm² | Dureté: >270<350 HB (ISO: S3).

-6.2 ß-Laiton, bronze | Resist. traction: <700 N/mm² | Dureté: <200 HB (ISO: N4).

-6.3 a-Laiton | Resist. traction: <700 N/mm² | Dureté: <200 HB (ISO: N3).

-6.4 Metal AMPCO | Resist. traction: <1500 N/mm² | Dureté: <470 HB (ISO: N4).

-9.1 Matières dures cermets (céramiques métalliques) | Resist. traction: <1700 N/mm² | Dureté: <550 HB (ISO: H).

*Bon pour:

-6.1 Cuivre | Resist. traction: <350 N/mm² | Dureté: <100 HB (ISO: N3).

- Matériel : Carbure

- Revêtement: Brillant

- Type: double coupure pour utilisation générale